Transform Your Woodworking Experience: A Thorough Overview of Modern Equipment Options

Modern woodworking is advancing with the introduction of sophisticated machinery. CNC routers and laser cutters enhance precision and effectiveness, making them invaluable to woodworkers. These devices permit intricate styles while decreasing waste. The option procedure can be overwhelming. Comprehending the crucial features and exactly how to incorporate these modern technologies right into conventional methods is essential. What factors should one consider when choosing the right machinery? The responses might change a woodworker's technique.

The Increase of CNC Routers in Woodworking

As woodworking remains to progress, the appearance of CNC routers has actually transformed typical methods right into cutting-edge manufacturing procedures. These computer-controlled devices enable accurate cutting, shaping, and engraving of wood, greatly enhancing the efficiency and precision of woodworking jobs. Unlike hands-on techniques, CNC routers can duplicate designs with consistent top quality, lowering the danger of human mistake.

The adaptability of CNC routers makes them suitable for a wide variety of applications, from intricate carvings to massive manufacturing runs. They can take care of complicated geometries and various products, providing to both hobbyists and expert woodworkers.

Additionally, the integration of CAD (Computer-Aided Design) software promotes the seamless change from design to production, permitting for faster project turnaround times. Consequently, CNC routers are ending up being significantly preferred, making it possible for woodworkers to push the limits of creative thinking while enhancing their process. This technical improvement notes a notable adjustment in the woodworking landscape.

Checking out the Perks of Laser Cutters

A growing variety of woodworkers are uncovering the advantages of laser cutters, which use unequaled accuracy and convenience fit wood and various other products. These devices utilize extremely focused laser beam of lights to reduce, inscribe, and etch styles with remarkable precision, permitting intricate information that typical methods may battle to attain. The capability to swiftly create complex patterns can considerably enhance performance, allowing artisans to total tasks in a fraction of the time.

Additionally, laser cutters create minimal waste, as the reducing process is accurate and reduces excess product. This effectiveness not just conserves sources yet additionally decreases costs connected with resources. Additionally, their flexibility enables woodworkers to try out a variety of materials past wood, consisting of acrylic and fabric, broadening creative opportunities. Subsequently, laser cutters are becoming vital tools in contemporary woodworking, attracting both hobbyists and experts aiming to boost their craft.

Necessary Features to Try To Find in Modern Tools

When choosing contemporary woodworking devices, 3 crucial features stand out: adaptability, longevity, and precision. Precision guarantees that every finish, joint, or cut is exact, resulting in professional-quality results. Tools that offer outstanding accuracy not only improve the workmanship however additionally minimize waste, conserving time and sources.

Resilience is important for long life and constant performance. Premium products and robust building and construction secure versus damage, enabling devices to endure strenuous use in different woodworking projects.

Adaptability permits a solitary tool to carry out multiple features, making it a useful enhancement to any workshop. Tools that can adapt to various tasks and materials enhance effectiveness and reduce the requirement for excessive equipment.

How to Pick the Right Equipment for Your Projects

Furthermore, spending plan restraints frequently determine equipment options. Premium devices can be expensive, yet purchasing dependable equipment can enhance productivity and outcome high quality.

Power needs and the accessibility of substitute parts likewise merit consideration, especially for lasting maintenance.

Tips for Integrating Modern Technology Into Traditional Woodworking Methods

Incorporating innovation into typical woodworking methods can boost craftsmanship and effectiveness. Woodworkers can start by making use of electronic design software to create accurate strategies and versions, permitting even more precise cuts and joints. These programs can additionally assist in the exploration of complex designs that might be difficult by hand.

Including CNC equipments can furthermore simplify production, making it possible for artisans to reproduce complex patterns with consistency. It is necessary to maintain the tactile experience of woodworking; incorporating CNC job with hand-finishing strategies can produce outstanding results.

Taking on laser inscription devices allows for personalization and in-depth embellishments, including a modern touch to typical pieces. On top of that, using electronic calipers and laser levels can enhance dimensions, guaranteeing higher precision in every job. By mixing these technologies with classic methods, woodworkers can preserve the virtuosity of their craft while welcoming development.

Frequently Asked Questions

What Is the Ordinary Life-span of Modern Woodworking Machinery?

The ordinary life-span of contemporary woodworking machinery generally ranges from 10 to 20 years, depending upon upkeep, top quality, and usage. Lumber Stacker. Normal servicing can prolong this life expectancy, while disregard might result in early damage and malfunction

Just How Much Maintenance Do These Makers Generally Require?

Modern woodworking machinery commonly calls for regular maintenance, consisting of cleansing, lubrication, and routine assessments. This ensures peak performance and long life, with a lot of equipments requiring complete maintenance every 6 months to a year, depending on use intensity.

Can I Use Standard Strategies With Modern Equipment?

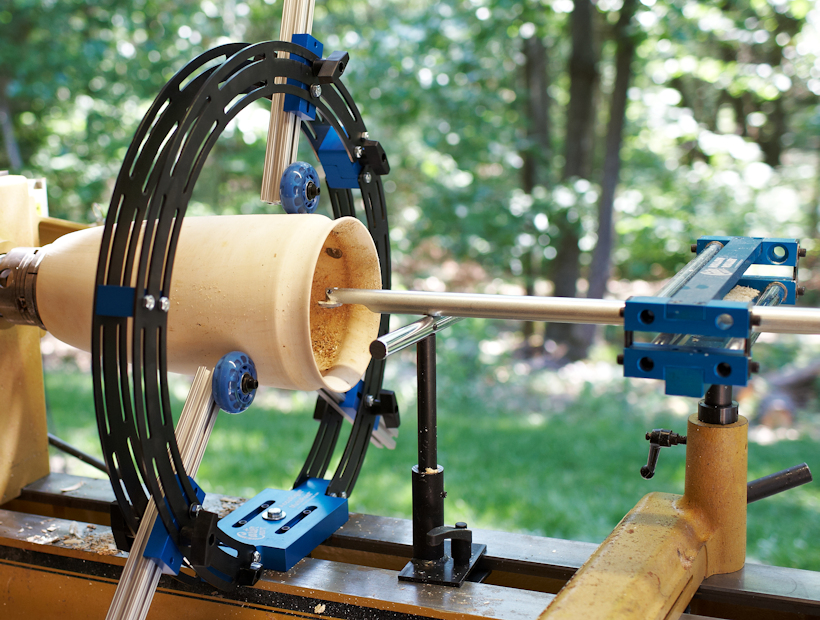

Yes, typical methods can be this contact form successfully utilized together with contemporary machinery - Rotary Claming System. Several artisans mix both techniques, enhancing performance while protecting craftsmanship, permitting for a harmonious integration of classic approaches with modern devices in woodworking jobs

What Safety Features Should I Try To Find in Woodworking Devices?

When selecting woodworking devices, one need to focus on security functions such as blade guards, emergency quit buttons, anti-kickback devices, and dust collection systems, making certain a safer working setting and lessening the danger of accidents throughout operation.

Are There Financing Options for Purchasing Modern Woodworking Equipment?

Several producers and retailers use financing alternatives for buying contemporary woodworking machinery. These may consist of time payment plan, renting arrangements, and credit history alternatives, making it possible for purchasers to take care of prices while purchasing essential devices for explanation their woodworking jobs.

Modern woodworking is progressing with the introduction of sophisticated equipment. When picking modern woodworking devices, three essential attributes stand out: accuracy, versatility, and sturdiness. The typical life expectancy of modern woodworking machinery usually varies from 10 to 20 years, depending on high quality, usage, and maintenance. Modern woodworking machinery normally needs normal upkeep, consisting of cleansing, lubrication, and regular examinations. Many manufacturers and stores use funding alternatives for acquiring contemporary woodworking equipment.